Send us your job details for a personalised quote

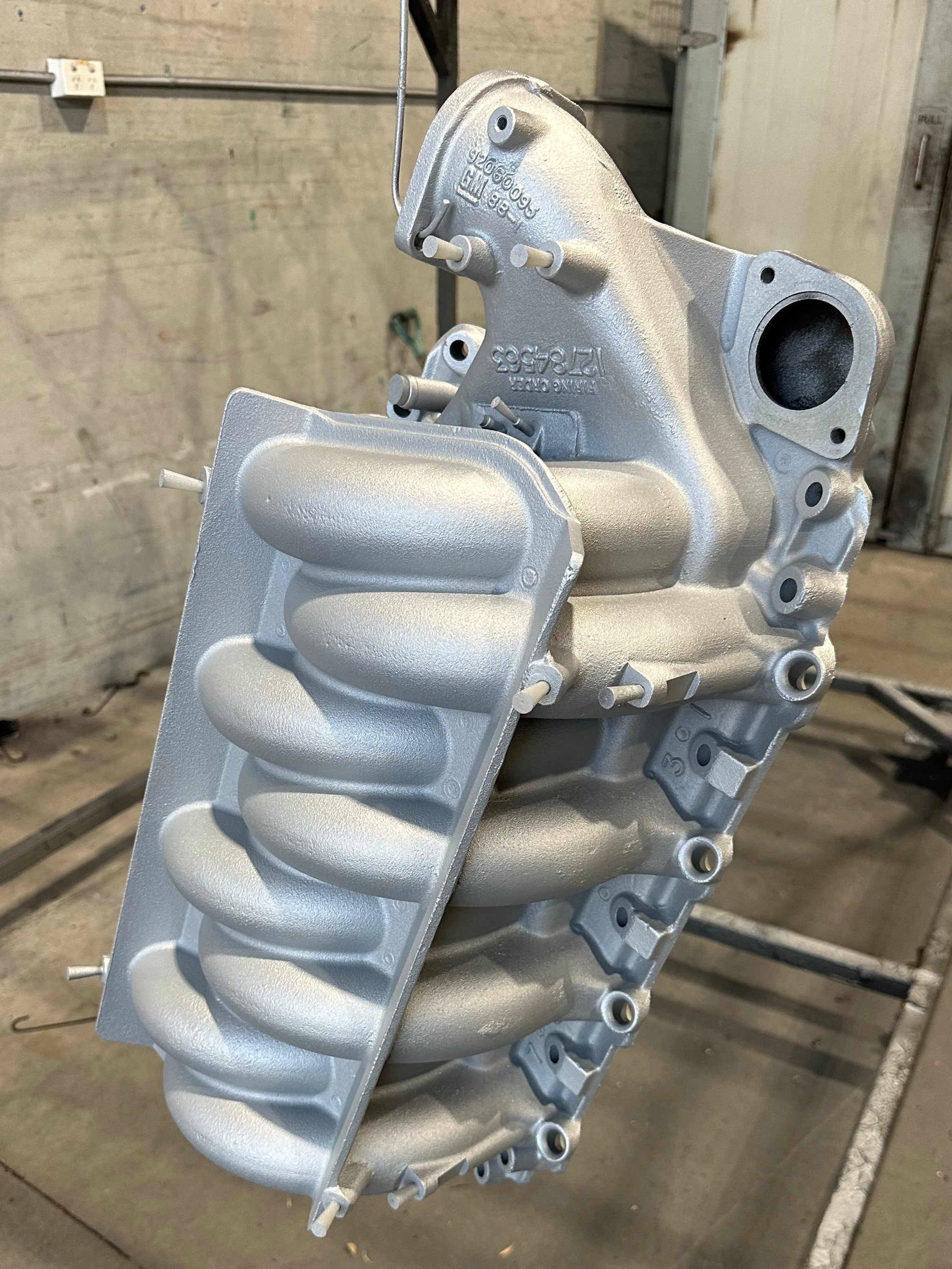

Powder Coating

Powder coating is a highly effective finishing process used in various industries, including automotive manufacturing. This technique involves applying a dry powder to a surface, which is then cured under heat to form a durable and protective layer. The process is particularly advantageous for automotive parts, as it enhances both aesthetics and performance.

The powder coating process begins with the preparation of the substrate, which is typically metal. Proper surface preparation is crucial, as it ensures optimal adhesion of the powder. This may involve cleaning, sanding, or blasting the surface to remove any contaminants. Once prepared, the powder is applied using an electrostatic spray gun, which charges the powder particles, allowing them to adhere to the grounded surface.

After application, the coated parts are placed in an oven where the powder melts and flows, forming a smooth, even layer. The curing process typically occurs at temperatures ranging from 180°C to 200°C for a duration of 10 to 30 minutes, depending on the specific powder formulation. This heat treatment not only solidifies the coating but also enhances its chemical and mechanical properties.

One of the primary benefits of powder coating is its superior durability compared to traditional liquid paints. Powder-coated surfaces exhibit increased resistance to scratches, chipping, fading, and corrosion. In fact, studies indicate that powder-coated finishes can be up to three times more durable than conventional paint finishes. This makes powder coating an ideal choice for automotive components that are exposed to harsh environmental conditions.

Additionally, powder coating is an environmentally friendly option, as it produces minimal volatile organic compounds (VOCs) during the application process. This characteristic aligns with the growing demand for sustainable manufacturing practices in the automotive industry. Furthermore, excess powder can be reclaimed and reused, reducing waste and lowering production costs.

In terms of aesthetics, powder coating offers a wide range of colours and finishes, including matte, gloss, and textured options. This versatility allows automotive manufacturers to achieve specific design requirements while maintaining the functional benefits of the coating. The ability to customize finishes also enhances the overall appeal of vehicles, contributing to brand differentiation in a competitive market.

Powder coating is a highly effective and sustainable finishing process that provides significant advantages for automotive applications. Its durability, environmental benefits, and aesthetic versatility make it a preferred choice for enhancing the performance and appearance of automotive parts. As the automotive industry continues to evolve, the adoption of powder coating technology is likely to increase, further solidifying its role in high-performance automotive manufacturing.